OT Cybersecurity & IEC 62443 Training Workshop in Mumbai in May 2024

Join us on 2nd and 3rd May 2024 in Mumbai, India for the Abhisam OT Cybersecurity Training workshop. This is the fourth time that Abhisam’s India office will be holding the workshop in the past few months. As you probably know by now, Abhisam’s flagship course is the popular Certified Industrial Cybersecurity Professional course (CICP course) that is taken by

What is IEC 62443-4-3?

This short guide gives you an introduction to the new IEC 62443-4-3 part of the IEC 62443 set of standards. Note: To learn about Industrial Cybersecurity and IEC 62443, you can take the Abhisam Certified Industrial Cybersecurity Training Course here. This leads to certification as a CICP after you complete all the modules and pass the exam. It is better

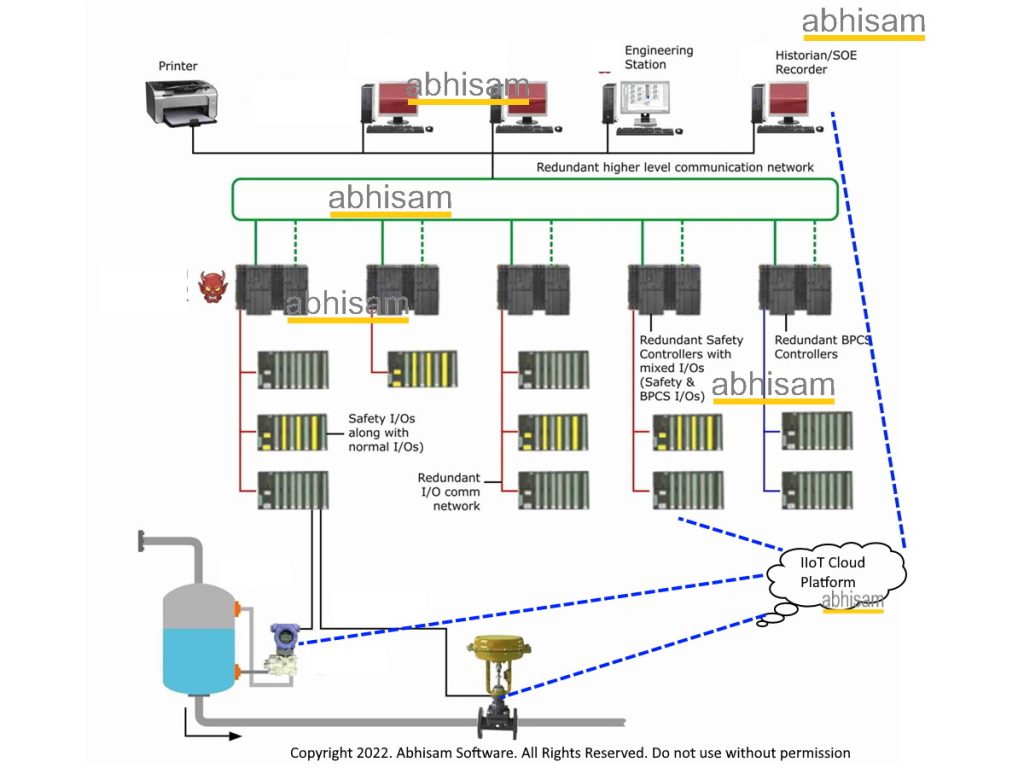

ICS Cyber Security for Chemical Plant

ICS Cyber Security for Chemical plants- Introduction Industrial Control Systems (ICS) are used in all modern chemical plants. These Industrial Control Systems play a crucial role in maintaining the efficiency, reliability, and safety of chemical plant operations. Currently the global chemical industry is facing challenging times related to energy costs, raw material costs and supply chain problems. The last thing

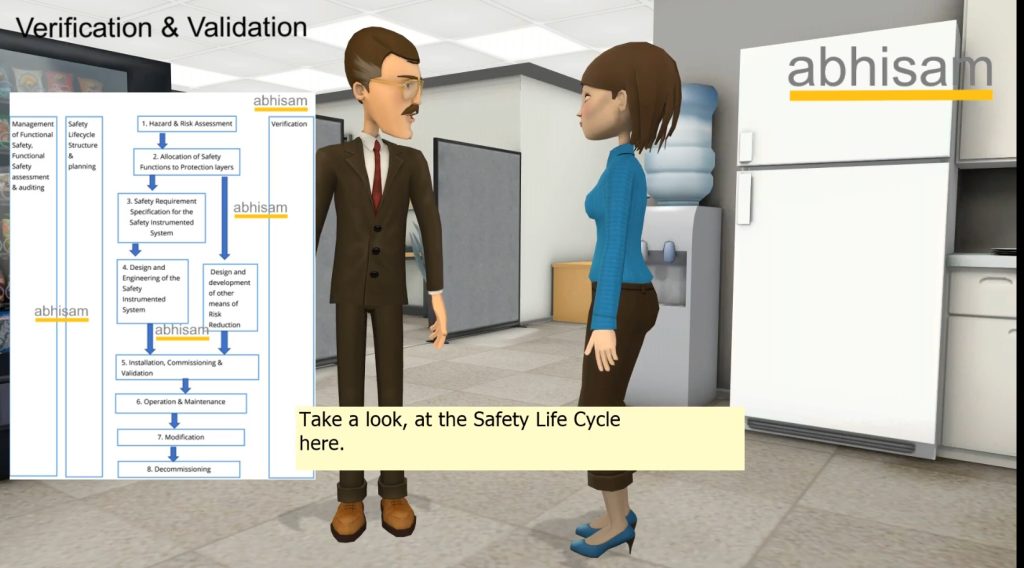

What is the difference between Verification and Validation in Functional Safety?

In this short guide, we will learn about two important concepts in the Functional Safety world, Verification and Validation and the difference between the two. What is Verification and Validation? Although colloquially these two words may sound similar, yet in the Functional Safety World, they are distinct concepts and different from each other, as different as chalk and cheese. To

How to get certified as a Professional for less

Upgrade your skillset and get certified as a Professional for less Black Friday is near and this is a great opportunity to get certified as a Professional for much less than usual! Abhisam’s Black Friday deal is live now! Get your Abhisam Course Discount Coupons here. It offers you 15% off on all courses and Subscriptions/Payment Plans for Courses.

OT Cyber Security Awareness Training Course coming soon

Abhisam is pleased to announce that the Abhisam OT Cyber Security awareness training course will soon be available online. This OT security awareness etraining is a great way to train large numbers of your employees in the basics of OT Cyber Security/Industrial cyber security. This course can be deployed globally via the Abhisam Learning Portal and managers or training administrators