In this short guide, we will learn about two important concepts in the Functional Safety world, Verification and Validation and the difference between the two.

What is Verification and Validation?

Although colloquially these two words may sound similar, yet in the Functional Safety World, they are distinct concepts and different from each other, as different as chalk and cheese. To have a quick overview of this, you can watch the short video below. If you would prefer to read about it please scroll below.

And if you would like to learn and get certified as a Functional Safety Professional, then take the Abhisam Functional Safety courses such as the Functional Safety Professional (Level 1) and the Safety Instrumented Systems Professional.

Looking for a free Functional Safety book?

This is the easiest, free and fastest way to come up to speed as regards Functional Safety and Sil. Grab your copy from here Free Functional Safety Book pdf | Abhisam

So what is the difference between Verification and Validation?

Watch the video below to understand in an easy way what these terms mean. If you would like to read about it then scroll below for a text explanation.

What is Verification?

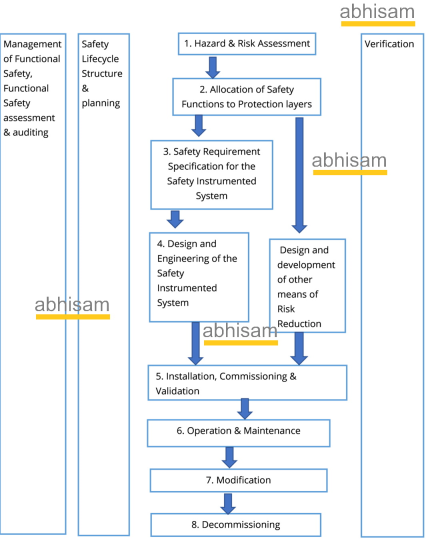

Verification is an activity, carried out by an entity that is sufficiently independent, which checks whether a claimed activity has actually been performed. As you know, if you follow the Safety Life Cycle, as given in IEC 61511, there are several phases during this and each phase is done by one or more persons, teams, departments or even different organizations. For example the Hazard and Risk Assessment may be done by an outside organization , whereas the Safety Requirements Specification phase may be carried out by the end user of the SIS.

Somebody needs to verify if these activities were really done in practice, or not. This is what is meant by verification. The verification activities should be done after every phase of the lifecycle. Validation activities are done only during the Installation, Commissioning and Validation phase. Although one can argue that periodic proof testing that happens regularly is a form of re-validation testing. This is a form of performance testing.

Sufficient Independence of Verification and Validation activities

To avoid bias, the verification work is done by somebody who has no connection with carrying out the work. This means the same person, department or company that did the work, cannot simply declare that they did it. It has to be checked by somebody else. This ensures that these phases are actually done and is one of the most important ways in which we are assured that the plant or equipment is indeed safe.

Is verification just checking the SIL and PFDavg calculation?

Some people unfortunately think that verification is just checking the calculations for PFDavg. No, this is not correct. Of course these calculations have to be checked and verified by a third party (who may be simply a different department in your company), but it is just a part of the entire verification activity. You can refer to the Safety Life Cycle above.

Learn more about the Safety Life Cycle here

What is Validation?

Validation is where the end user of your Safety Instrumented System actually tests it under real life conditions and is satisfied that it will work in reality. This is as they say, “where the rubber meets the road”. Your car may look great in a Showroom under fancy lights, but how does it run on the road? You can only find out once you drive it down the ramp from the car dealer lot on to the freeway. Whether it is as great as it looks, or you got yourself a lemon.

Similarly, your Safety Instrumented System may look great on paper, triple redundant voting logic and all those bells and whistles, but does it really shut down the plant when demanded, within the process safety time and without breaking anything else? Or does it simply trip without any demand?

You can find out only when the SIS is first proof tested in the field, usually during the Site Acceptance Test (SAT). This demonstration of actual fitness for use, in a real world condition, is known as Validation. The validation processes ensure that the specified requirements and standards are met. Note that a modern SIS would have hardware as well as software and the overall validation test will test hardware as well as the software.

Does Validation also need Verification?

Sure. You want to be 100% sure that somebody actually tested the SIF in the plant, under real world conditions, not just ticked some boxes on a piece of paper that says “Tested OK”. So some independent third party- could be another person, department or outside organization, who is not involved in the design or work related to the SIS, witnesses that the SIS was indeed actually really tested in the field by real people in real world conditions. That is why this is also sometimes known as Witness Testing or Witness Validation Testing. This act of some third party witnessing that the proof test is actually carried out, is the Verification of the Validation. It needs to be documented of course and preferably with photos and videos. Although the plant owner may not allow you to post it on Instagram or Twitter.

When do we carry out Verification?

We are supposed to carry out a Verification after every phase of the lifecycle.

Who carries out Verification?

Any independent person, department or organization who is not connected with the making of the SIS can carry out the Verification. However the person who has built the SIS or the vendor who has supplied the parts and/or system cannot carry out the verification, as they are an interested party and could be biased in their opinion.

Who carries out Validation?

The end user of the system, such as for example the Plant Manager in whose plant the SIS is being installed has to carry out the validation under his/her supervision.

Where to learn more and get certified at a low cost?

Instead of spending thousands of dollars on old courses from other providers, take the most cost effective and the easiest course to understand Functional Safety, SIL and Safety Instrumented Systems.

Taken by hundreds of learners from marquee companies like Aker, GASCO, TOTAL, Kongsberg, Exyte, Thai Oil, Marathon Oil (just to name a few), these courses will immediately build up your competency in the Functional Safety domain. Based on IEC 61508 and IEC 61511, these courses are not just a video of a guy speaking but consist of animations, videos and real life examples and situations that help you quickly gain confidence in taking up Functional Safety related projects and maintenance work.

Contact us at sales@abhisam.com to know more

Want to check out your knowledge on Functional Safety and SIL? Take the free Functional Safety Mock Test to quickly know how well you understand it.